QUALITY CONTROL

Over the years, we have optimized our control systems at every stage of the process.

In 2004, we established a quality management system in accordance to ISO 9001 norm.

In 2004, we established a quality management system in accordance to ISO 9001 norm.

Nowadays, we can boast an extremely efficient Quality Department following every step of the production process, starting from the raw material suppliers selection.

Quality personnel monitor every production step with scheduled tests.

Before shipment, batches are checked and packed according to the Customer specifications.

IN LINE QUALITY CONTROL

The production start-up is monitored by Quality Department inspectors.

During production, forgings are then picked at regular intervals for hot inspection.

During production, forgings are then picked at regular intervals for hot inspection.

These quality controls grant complete compliance of the product, essential to maintain

Customers’ fidelity and confidence over the years.

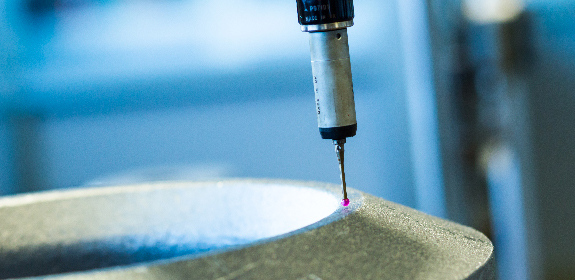

METAL TESTING LAB

Incoming steel is checked by our internal metal testing lab to verify quality and conformity to the specs.

Our up-to-date equipment includes:

Our up-to-date equipment includes:

- Quantometer for steel chemical composition testing;

- Metallographic microscope for the control of steel grain and purity;

- Muffle furnace with jominy quenching fixture;

- Brinell and Rockwell hardness scale testers;

- Three-dimensional measurement table with a measurement volume of 1600 x 1000 x 1200 mm.