FORGING

Forgings can be tailor-made according to machining needs: optimizing the blank design with the right stock allowance reduces both forging and machining costs.

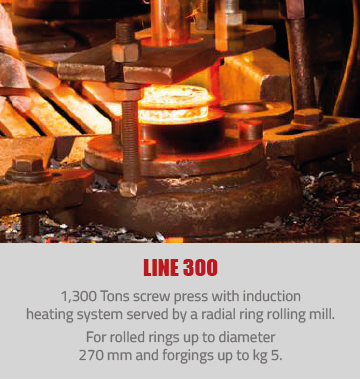

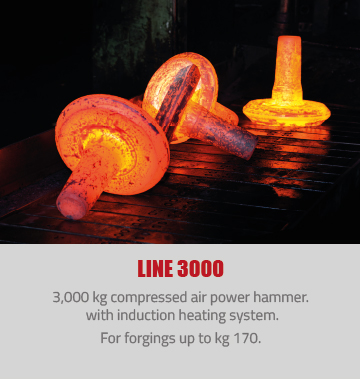

According to Customer’s needs, forgings are produced either with the hammer or with screw or mechanical presses of different powers.

Our production lines are equipped with induction furnaces to heat the raw material: steel bars can be hot-sheared directly in line or cold-sheared, in case of smaller diameters.

Forgings range from 1 to 170 kg: wind turbine pinions, bevel crowns and pinions, gears, wheel hubs, gear housings, diff cases and flanges are amongst our most significant productions.

RING ROLLING

Diameters range from 120 to 800 mm, with a maximum height of 150 mm.

Our two radial-axial ring rolling mills allow a very high product quality and precision, both from geometrical and visual points of view.

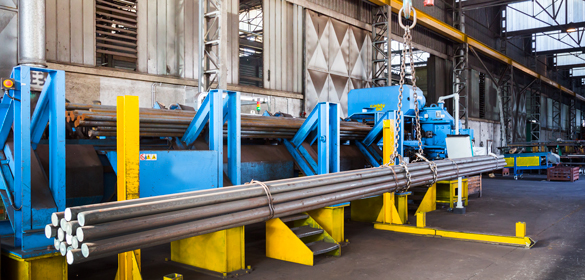

RAW MATERIAL AND WAREHOUSE

To be able to quickly respond to our worldwide Customers needs, we have a sizeable steel warehouse.

Our Purchasing Department makes sure raw material is always on hand and checks the timeliness of our suppliers’ deliveries.